KAMAK is a complete, low-mechanization solution designed to substantially increase the treatment capacity of your lagoons with ease. Robust and reliable, KAMAK technology allows you to significantly boost the capacity of your aerated lagoons while keeping operations simple and aligned with your operational capabilities.

Commercial and municipal / Kamak

Durable Investment to Enhance Aerated Lagoon Performance

Benefits of Adding KAMAK Technology to an Aerated Lagoon

Investment that evolves with your needs

Guaranteed effluent treatment performance for lagoons

Technology that meets regulatory requirements

Safe access on platforms

FAQ

KAMAK is a treatment technology whose performance can be referenced in the technical information sheet issued by the Quebec Ministry.

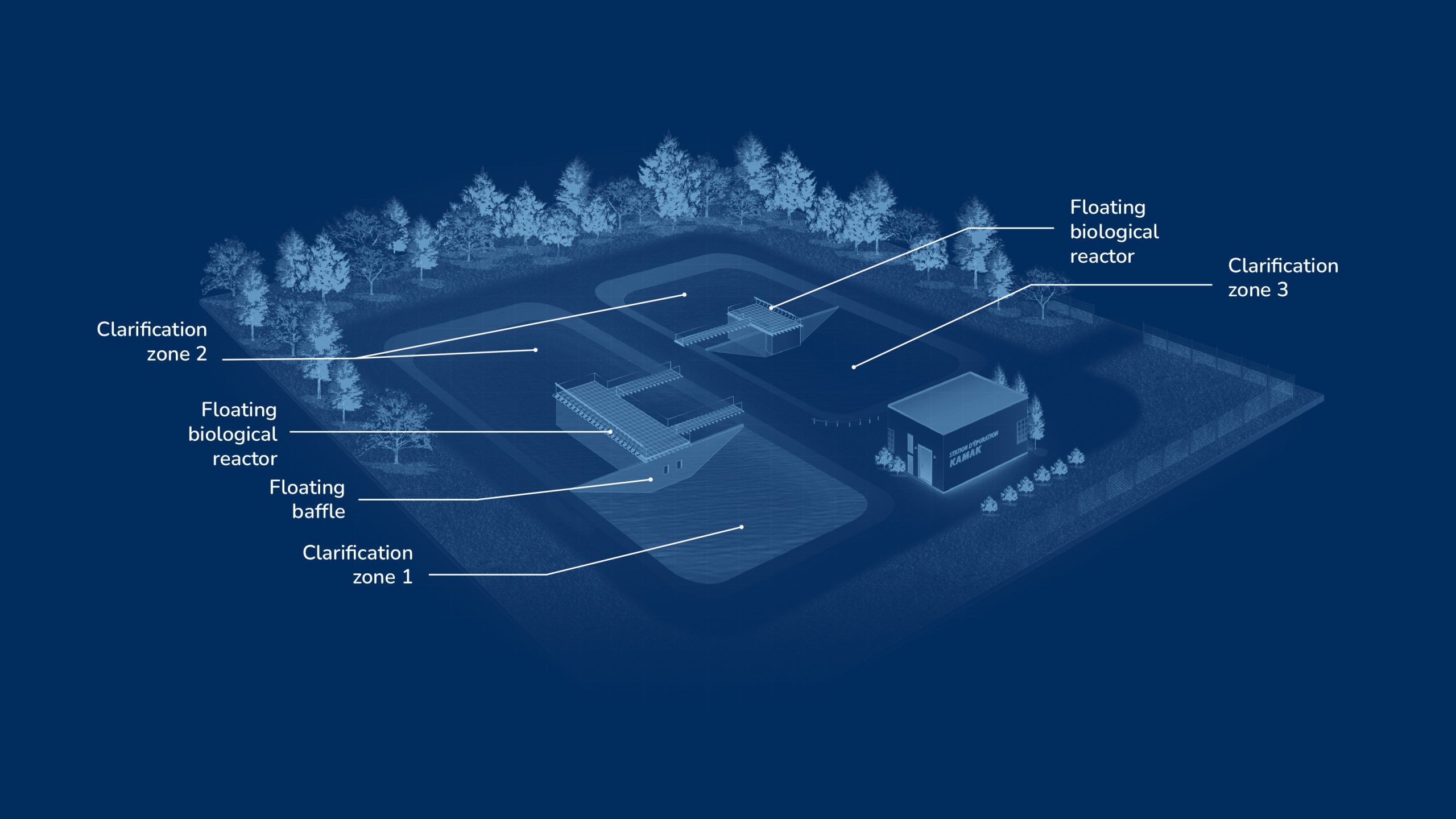

Unlike process equipment, implementing the KAMAK treatment train in an aerated lagoon upgrade project does not require additional upstream or downstream process units.

It is important to note that with KAMAK, the hydraulic retention time of the treatment train can be reduced to less than 12 days (even down to 6 days!) without adding extra treatment equipment or infrastructure. This represents a significant advantage, allowing you to substantially increase your treatment capacity.

KAMAK technology has been designed to meet the strictest effluent standards established by the MELCCFP for municipal wastewater treatment plants. KAMAK achieves treatment performance superior to conventional aerated lagoons (performance details are available in the MELCCFP technical information sheet).

Key advantages of KAMAK technology include:

-

Hydraulic retention time reduced to as little as 6 days

-

No additional pre-treatment or post-treatment equipment required

-

Sludge accumulation rates up to 40% before requiring emptying

-

Ammoniacal nitrogen removal even in cold water

With over 10 years of experience upgrading aerated lagoons, KAMAK has proven its effectiveness!

KAMAK technology is installed directly into the aerated lagoons being upgraded, without the need for additional infrastructure or equipment. Its biological treatment process makes it one of the least mechanized solutions on the market, requiring minimal attention.

Equipped with secure access points, KAMAK makes routine operations (visual inspections) simple and quick. Finally, our specialized technician teams are available to efficiently address any needs that may arise.

KAMAK is a technology with over 10 years of proven experience. This simple and robust solution is designed to meet the needs of Quebec municipalities. Whether your lagoons have sloped or vertical walls, are in-ground excavated, and regardless of the flow or load to be treated, our engineers will determine the optimal configuration to increase the capacity of your wastewater treatment plant.

We regularly organize site visits in collaboration with participating municipalities—join us!

Capable of achieving hydraulic retention times as short as 6 days, KAMAK technology offers unmatched capacity upgrade potential. The floating biological reactors installed in lagoons are sized according to the load to be treated, allowing them to adapt to your actual treatment needs.

KAMAK is the only technology of its kind that can achieve hydraulic retention times as low as 6 days without the need for pre- or post-treatment.

Review our case study for yourself, which compares two scenarios for increasing the capacity of a wastewater treatment plant composed of aerated lagoons: Discover More